Rear Wheel

Rear Wheel

Removal

1. Place the motorcycle on the center stand.

2. Remove the seat. Next, remove the rear fender installation bolts and remove the rear fender.

3. Remove the axle nut cotter pin and axle nut.

4. Loosen the rear axle pinch bolt.

1 Pinch belt

5. Remove the tension bar from the brake caliper assembly. The tension bar can be removed by removing the cotter pin and nut from the tension bar bolt.

1. Cotter pin 2. Tension bar nut

6. While supporting the brake caliper, pull out the rear axle.

7. Hold up the brake caliper assembly.

8. Move the wheel to the right side to separate it from the final gear cases and remove the rear wheel.

Rear axle inspection

Remove any corrosion from the axle with fine emery cloth. Place the axle on a surface plate and check for bends. If bent, replace axle. Do not attempt to straighten a bent axle.

Rear wheel inspection

NOTE: Refer to "Tubeless tire and aluminum wheel manual" for the proper tubeless and aluminum wheel servicing.

1. Check for cracks, bends or warpage of wheels. If a wheel is deformed or cracked, it must be replaced.

2. Check wheel run-out. If the deflection exceeds the tolerance below, check the wheel bearings or replace the wheel as required.

Rim-run-out limits:

Vertical - 2 mm (0.08 in) Lateral - 2 mm (0.08 in)

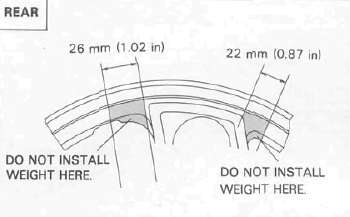

3. Check wheel balance. Rotate the wheel lightly several times and observe resting position. If the wheel is not statically balanced, it will come to reset at the same position each time. Install an appropriate balance weight at lightest position (at top).

NOTE: The wheel should be balanced with the brake disc installed.

CAUTION: Tire and wheel should be balanced whenever either one is changed or replaced. Failure to have wheel balanced can result in poor performance, adverse handling characteristics, and shortened tire life.

4. After installing a tire, ride conservatively to allow the tire to seat itself on the rim properly- Failure to allow proper seating may cause tire failure, resulting in damage to the motorcycle and injury to the rider.

5. After repairing or replacing a tire, check to be sure the valve stem lock nut is securely fastened. It not, torque it as specified.

Tightening torque:

1.5 Nm (0.15 m-kg 1.1 ft lb)

Replacing wheel bearings

If the bearings allow play in the wheel hub or if wheel does not turn smoothly, replace the bearings as follows:

1. Clean the outside of the wheel hub.

2. Drive the bearing out by pushing the spacer aside and tapping around the perimeter of the bearing inner race with a soft metal drift pin and hammer. The spacer "floats" between the bearings. Both bearings can be removed in this manner.

WARNING: Eye protection is recommended when using striking tools.

3. To install the wheel bearing, reverse the above sequence. Use a socket that matches the outside race of the bearing as a tool to drive in the bearing.

CAUTION: Do not strike the center race or balls of the bearing. Contact should be made only with the outer race.

Installing rear wheel

1. Lightly grease lips of rear wheel oil seals.

2. Make sure the brake pads are installed properly and that there is enough gap to install the rear disc.

CAUTION: If it is necessary to separate the brake pads, do so carefully to avoid damage to the pad surface.

3. Install the wheel assembly and axle.

NOTE: Before installing the rear wheel, apply a light coating of lithium base grease to the final gear case splines.

When installing the rear wheel, be sure the splines on the wheel hub fit into the final gear case.

CAUTION: Always use a new cotter pin on the axle nut.

Tightening torque:

Axle nut: 105 Nm (10.5 m-kg, 75 ft lb)

Axle pinch bolt:6 Nm (0.6 m-kg, 4.3 ft-lb)

4. Install the rear fender and seat.