XJ700N & XJ700NC Service Manual

XJ700N & XJ700NC Service ManualTABLE OF CONTENTS:

Chapter 1, INTRODUCTION

Chapter 1, INTRODUCTION

YAMAHA XJ700N/NC

GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number (1) is stamped into the right side of the steering head pipe.

NOTE:

The vehicle identification number is used to identify your motorcycle and may be used to register your motorcycle with the licensing authority in your province or state.

Vehicle Identification Number:

XJ700N (Except for California): JYA1FG00*EA000101

XJ700NC (For California): JYA1JJ00*EA000101

ENGINE SERIAL NUMBER

The engine serial number (1) is stamped into the elevated part of the left rear section of the engine.

NOTE:

The first three digits of these numbers are for model identifications; the remaining digits are the unit production number.

Starting Serial Number: XJ700N (Except for California)

............... 1FJ-000101

XJ700NC (For California)

............... 1JJ-000101

NOTE:

Designs and specifications are subject to change without notice.

IMPORTANT INFORMATION

ALL REPLACEMENT PARTS

1. We recommend to use Yamaha genuine parts for all replacements. Use oil and/or grease recommended by Yamaha for assembly and adjustment.

GASKETS, OIL SEALS, AND O-RINGS

1. All gaskets, seals, and O-rings should be replaced when an engine is overhauled. All gasket surfaces, oil seal lips, and 0-rings must be cleaned.

2. Properly oil all mating parts and bearings during reassembly. Apply grease to the oil seal lips.

LOCK WASHERS/PLATES AND COTTER PINS

1. All lock washers/plates (f, and cotter pins must be replaced when they are removed. Lock tab(s) should be bent along the bolt or nut flat(s) after the bolt or nut has been properly tightened.

BEARINGS AND OIL SEALS

1. Install the bearing(s) (1) and oil seal(s) (2) with their manufacturer's marks or numbers facing outward. (In other words, the stamped letters must be on the side exposed to view.) When installing oil seal(s), apply a light coating of light-weight lithium base grease to the seal lip(s). Oil the bearings liberally when installing.

Do not use compressed air to spin the bearings dry. This causes damage to the bearing surfaces.

CIRCLIPS

1. All circlips should be inspected carefully before reassembly. Always replace piston pin clips after one use. Replace distorted circlips. When installing a circlip (1), make sure that the sharp-edged corner (2) is positioned opposite to the thrust (3) it receives. See the sectional view. (4) Shaft

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the correct special tool will help prevent damage caused by the use of improper tools or improvised techniques.

FOR TUNE UP

1. Inductive Tachometer P/N YU-08036

This tool is needed for detecting engine rpm.

2. Inductive Timing Light P/N YM-33277

This tool is necessary for checking ignition timing.

3. Compression Gauge P/N YU-33223

This gauge is used to measure the engine compression.

4. Y.I.CS. ShutoffTool P/N. YM-08025

This tool is needed to measure the carburetor fuel level.

5. Vacuum gauge P/N, YU-08030

This gauge is needed for carburetor synchronization.

6. Fuel level gauge P/N. YM-01312

This tool is needed to measure the carburetor fuel level.

FOR ENGINE SERVICE

1. Tappet adjusting tool P/N. YM-01245

This tool is necessary to replace valve adjusting pads.

2. Universal Clutch Holder P/N.YM-91042

This tool is used to hold the clutch when removing or installing the clutch boss lock nut.

3. Valve spring compressor P/N. YM-04019

This tool must be used for removing and installing the valve assemblies.

4. Valve guide remover P/N. YM-01225

This must be used to remove the valve guides.

5. Valve guide installer P/N. YM-04017

This tool is needed for proper installation of the valve guides.

6. Valve guide reamer P/N. YM-01227

This must be used when replacing the valve guide.

7. Valve seat cutter P/N. YM-91043

This tool is needed to re-surface the valve seat.

8. Rotor holding tool P/N. YM-04043

This tool is used to hold the A.C. Generator rotor during removal and installation.

9. Rotor puller P/N. YM-01080

This tool is needed to remove the A.C. Generator.

10. Rotor puller attachment P/N. YM-04052

This tool is needed when removing the A.C. Generator rotor together with the rotor puller.

11. Piston ring compressor P/N. YM-04044

This is used to compress piston rings when installing the cylinder.

12. Piston base P/N. YM-01067

Use 4 of these to hold the pistons during cylinder installation.

FOR SHAFT DRIVE SERVICE

1. Middle drive pinion holder P/N. YM-33222

This tool is needed when measuring gear lash.

2. Dial Gauge P/N. YU-03097

This gauge is used to measure gear lash.

3. Damper Spring Compressor P/N. YM-33286

This tool is needed to disassemble and reassemble the middle gear damper.

4. Middle-Drive-Shaft-Bearing-Retainer Wrench P/N. YM-04057

This tool is used to loosen or tighten the bearing retainer.

5. Final Gear Holding Tool P/N. YM-01254

This tool is needed when measuring gear lash.

6. Final-Drive Gear Lash Measurement Tool P/N. YM-01230

This tool is used to measure gear lash.

7. Middle and Final Gear Holding Tool P/N.YM-01229

This tool is used when measuring gear lash.

8. Final Drive Shaft Bearing Retainer Wrench P/N. YM-40450

This tool is used to remove and install the bearing retainer.

FOR CHASSIS SERVICE

1. T-Handle P/N. YM-01326— (1) Fork Damper Rod Holder P/N. YM-33298—(2)

These tools are used to loosen and tighten the front fork cylinder holding bolt.

2. Ring Nut Wrench P/N. YU-01268 — (1) YU-33975 — (2)

These tools are used to loosen and tighten the steering ring nut.

3. Front Fork Seal Driver (weight) P/N. YM-33963 — (1) Adapter (38 mm) P/N. YM-01372 —(2)

These tools are used when installing the fork seat.

4. Front Fork Cap Socket (17 mm) P/N. YM-01104

This tool is used when removing the cap bolt.

FOR ELECTRICAL COMPONENTS

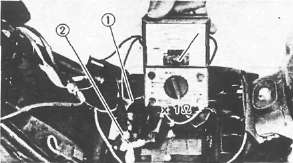

1. Pocket Tester P/N.YU-03112

This instrument is invaluable for electrical system inspection and adjustment.

2. Electro Tester P/N.YU-33260

This instrument is necessary for ignition system inspection.

Chapter 2, Periodic Maintenance, Inspections and Adjustments

Chapter 2, Periodic Maintenance, Inspections and AdjustmentsINTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation and a longer service life. The need for costly overhaul work will be greatly reduced. This information applies to vehicles already in service as well as new vehicles that are being prepared for sale. All service technicians should be familiar with this entire chapter.

Electrical Maintenance

Electrical MaintenanceBATTERY

1. Disconnect:

• Negative lead (1)

• Positive lead (2)

• Breather hose (3)

2. Pull:

• Battery

3. Check:

• Fluid level

Incorrect — Refill.

Fluid level should be between upper (1) and lower (2) level marks.

Refill with distilled water only; tap water contains minerals harmful to a battery.

2. Connect:

• Breather hose

Be sure the hose is properly attached and routed.

3. Inspect:

• Breather hose Obstruction — Remove. Damage — Replace.

HOW TO ROUTE BATTERY BREATHER PIPE.

CAUTION:

Always charge a new battery before using it to ensure maximum performance.

Charging Current: 1.4 amps/10 hrs

Specific Gravity: 1.280 at 20°C(68°F)

Battery electrolyte is dangerous; it contains sulfuric acid and therefore is poisonous and highly caustic. Always follow these preventive measure:

• Avoid bodily contact with electrolyte as it can cause severe burns or permanent eye injury.

• Wear protective eye gear when handling or working near batteries.

Antidote (EXTERNAL):

• SKIN — Flush with water.

• EYES — Flush with water for 15 minutes and get immediate medical attention.

Antidote (INTERNAL):

• Drink large quantities of water or milk follow with milk of magnesia) beaten egg, or vegetable oil. Get immediate medical attention.

Batteries also generate explosive hydrogen gas, therefore, you should always follow these preventive measures:

• Charge batteries in a well-ventilated area.

• Keep batteries away from fire, sparks, or open flames (e.g., welding equipment, lighted cigarettes, etc.)

• DO NOT SMOKE when charging or handling batteries.

KEEP BATTERIES AND ELECTROLYTE OUT OF REACH OF CHILDREN.

HEADLIGHT

Headlight Bulb Replacement

1. Remove:

• Securing screws (1) (from light unit assembly/headlight body.)

2. Disconnect:

• Lead wire

3. Remove:

• Light unit assembly

4. Rotate:

• Bulb holder (1) Turn it counterclockwise.

5. Remove:

• Defective bulb

6. Install:

• Bulb (New)

Secure with bulb holder.

• Avoid touching glass part of bulb.

• Keep the bulb free from oil otherwise, transparency of glass, bulb life, and illumi-nous flux will be adversely affected.

• If oil gets on bulb, clean it with a cloth moistened thoroughly with alcohol or lacquer thinner.

Do not touch the headlight bulb when it is on, as the bulb generates enormous heat; keep flammable objects away.

7. Install:

• Light unit assembly (to headlight body.)

Headlight Beam Adjustment

Horizontal adjustment:

1. Rotate:

• Horizontal adjusting screw (1)

|

Horizontal Adjustment of Headlight Beam |

|

|

Adjusting screw |

Beam direction |

|

Turn clockwise |

- to Right |

|

Turn counterclockwise |

- to Left |

Vertical adjustment:

1. Rotate:

• Vertical adjusting screw (2)

|

Vertical Adjustment of Headlight Beam |

|

|

Adjusting screw |

Beam direction |

|

Turn clockwise |

1 to Raise |

|

Turn counterclockwise |

1 to Lower |

FUSE

The fuse box is under the indicator light panel. The main fuse is under the seat.

(1) Main fuse

(2) Other fuse block

(3) Spare fuses

Blown fuse replacement steps.

• Turn off ignition and the circuit.

• Install a new fuse of proper amperage.

• Turn on switches to verify operation of electrical device.

• If fuse blows immediately again, check circuit in question.

Do not use fuses of higher amperage rating than recommended. Extensive electrical system damage and fire could result from substitution of a fuse of improper amperage.

Maintenance Intervals Charts

Maintenance Intervals ChartsProper periodic maintenance is important. Especially important are the maintenance services related to emissions control. These controls not only function to ensure cleaner air but are also vital to proper engine operation and maximum performance. In the following maintenance tables, the services related to emissions control are grouped separately.

PERIODIC MAINTENANCE EMISSION CONTROL SYSTEM

|

ITEM |

REMARKS |

INITIAL ODOMETER READING |

|||||

|

1.000 km (600 mi) or 1 month |

*#1 7.000 km (4.400 mi) or 7 months |

"2 13,000 km (8,200 mi) or 13 months |

19,000 km {12.000 mi) or 19 months |

25,000 km [15,800 mi) or 25 months |

31,000 km <19.600m or 31 months |

||

|

Valve clearance |

Check and adjust valve clearance when engine is cold. |

o |

|||||

|

Spark plug |

Check condition. Adjust gap and clean. Replace at 13,000 km (or 13 months) and thereafter every 12,000 km (or 12 months). |

o |

Replace |

o |

Replace |

o |

|

|

Crankcase ventilation system |

Check ventilation hose for cracks or damage. Replace if necessary. |

o |

o |

o |

|||

|

Fuel line |

Check fuel hose and vacuum pipe for cracks or damage. Replace if necessary. |

|

o |

o |

o |

o |

|

|

Exhaust system |

Check for leakage. Retighten if necessary. Replace gasket(s) if necessary. |

o |

o |

o |

o |

o |

|

|

Idle speed |

Check and adjust engine idle speed. Adjust cable free play. |

o |

o |

o |

o |

o |

|

|

Carburetor synchronization |

Adjust synchronization of carburetors. |

o |

o |

o |

o |

o |

o |

|

•It is recommended that these items be serviced by a Yamaha dealer or other qualified mechanic. |

NOTE:

For farther odometer reading, repeat the above maintenance at the period establish; **1: Every 6.000 km (3,800 mi) "2. Every 12,000 km (7,600 mi) intervals.

GENERAL MAINTENANCE/LUBRICATION

|

No. |

ITEM |

REMARKS |

TYPE |

INITIAL ODOMETER READINGS |

|||||

|

1,000 km (600 mi) or 1 month |

**1 7,000 km (4,400 mi) or 7 months |

**2 13,000 km (8,200 mi) or 13 months |

**3 19,000 km (12,000 mi) or 19 months |

**4 25,000 km (15.800 mi) or 25 months |

31,000 km (19,600 mi or 31 months |

||||

|

1 |

Engine oil |

Warm-up engine before draining. |

See page 12 |

o |

o |

o |

o |

o |

o |

|

2 |

Oil filter |

Replace. |

— |

o |

o |

o |

|||

|

3 |

Air filter |

Clean with compressed air. Replace if necessary. |

— |

o |

o |

o |

o |

o |

|

|

4 |

Brake system |

Adjust free play. Replace pads if necessary. (Front) Replace shoes if necessary (Rear) |

o |

o |

o |

o |

o |

o |

|

|

5 |

Clutch |

Adjust free play. |

— |

o |

o |

o |

o |

o |

o |

|

6 |

Final gear oil |

Check oil level and leakage. Replace every 24,000 km (15,000 mi) or 24 months. |

SAE80 API GL-4 hypoid gear oil |

Replace |

o |

Replace |

|||

|

7 |

Control and meter cable |

Apply chain lube thoroughly. |

Yamaha chain and cable lube or SAE 10W30 motor oil. |

° |

o |

o |

o |

o |

o |

|

8 |

Rear arm pivot shaft |

Check bearings assembly for looseness. Moderately repack every 24,000 km (15,200 mi) |

Medium weight wheel bearing grease |

o |

|||||

|

9 |

Brake/ Clutch ever pivot shaft. |

Apply chain lube lightly. |

Yamaha chain and cable lube or SAE 10W30 motor oil. |

o |

o |

o |

o |

o |

|

|

10 |

Brake pedal and change pedal shaft |

Lubricate Apply chain lube lightly. |

Yamaha chain and cable lube or SAE 10W30 motor oil. |

o |

o |

o |

o |

o |

|

|

11 |

Center/Side stant pivots |

Check operation and lubricate. Apply chain lube lightly. |

Yamaha chain and cable lube or SAE 10W30 motor oil. |

o |

o |

o |

o |

o |

|

|

12 |

Front fork oil |

Check operation and leakage. |

— |

o |

o |

o |

o |

o |

|

|

13 |

Steering bearings |

Check bearings assembly for looseness. Moderately repack every 24,000 km (15,000 mi) |

Medium weight wheel bearing grease |

O |

o |

o |

o |

o |

|

|

14 |

Wheel bearings |

Check bearings for smooth rotation. |

— |

o |

o |

O |

o |

o |

|

|

15 |

Battery |

Check specific gravity and breather pipe for proper operation. |

— |

o |

o |

o |

o |

o |

|

|

16 |

A.C. Generator |

Replace generator brushes. |

o |

o |

|||||

|

17 |

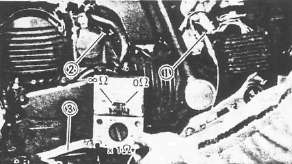

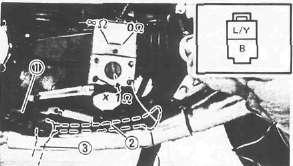

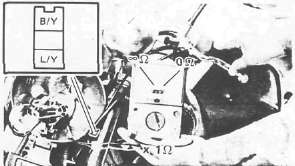

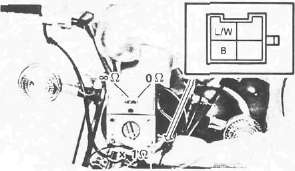

Sidestand switch |

Check and clean or replace if necessary. |

O |

o |

o |

o |

o |

o |

|

■ it is recommended that these items be serviced by a Yamaha Dealer or other qualified mechanic.

NOTE:

For greater odometer readings repeat the above maintenance at the period established, IE: **1: Every 6,000 km (3,800 mi), **2: Every 12,000 km (7,600 mi), **3: Every 18,000 km (11,400 mi), **4: Every, 24,000 km (15,200 mi) intervals.

Engine

EngineContents of Engine Maintenance:

Valve Adjustments

Valve AdjustmentsVALVE CLEARANCE ADJUSTMENT

(1)Pad (2) Valve lifter (3) Valve retainer (4)Spring seat (5)inner spring (6) Outer spring (7) Spring seat (8) Oil seal (9) Valve

|

A |

VALVE CLEARANCE (COLD): |

|

|

B |

Intake: |

0.11 -0.15 mm (0.0043-0.0059 in) |

|

C |

Exhaust: |

0.16-0.20 mm (0.0063-0.0079 in) |

Removal

1. Remove:

• Seat

• Fuel tank

• Ignition coil covers (1)

• Horns with stay (2)

2. Disconnect:

• Spark plug caps

3. Remove:

• Spark plugs

• Cylinder head cover

4. Remove:

• Emblem plate (Left)

Inspection and Adjustment

1. Measure:

• Valve clearance

NOTE:

Be sure piston is at Top Dead Center (TDC) on compression stroke when measuring clearance.

Valve clearance measurement steps:

• Turn the crankshaft counterclockwise with a 19 mm spanner (1) .

NOTE:

Valve clearance must be measured when the engine is cool to the touch.

• Align the "T" mark (for the No. 1 or No. 4 cylinder) on the timing plate with the stationary pointer (2). When the "T" mark is aligned with the stationary pointer (2), the piston is at top dead center TDC.

(3) Firing range for No. 1 cylinder

• Measure the valve clearance using a Feeler Gauge.

• Record the measured amount if the clearance is incorrect.

Intake Valve (cold): 0.11 —0.15 mm (0.0043 ~ 0.0059 in)

Exhaust Valve (cold): 0.16 —0.20 mm (0.0063 ~ 0.0079 in)

• Measure valve clearance, in sequence, for Nos. 2, 4, and No. 3 cylinders. Out of specification — Adjust clearance.

Firing Sequence: 1-2-4-3

(5) Front

A Crankshaft counterclockwise turning angle.

B Cylinder

(6) Combustion

2. Adjust:

• Valve clearance

Valve clearance adjustment steps:

• Position the valve lifter slots (intake and exhaust) opposite each other.

• Turn the camshaft until the lobe fully depresses the valve lifter and opens the valve.

• Attach the Tappet Adjusting Tool (1) (YM-01245) onto the cylinder head.

NOTE:

Make sure that the tool contacts the lifter (3) only, and not the pad (2).

• Carefully rotate the camshaft so that the pads can be removed. To avoid cam touching the adjusting tool, turn cams as shown.

Intake: Carefully rotate CLOCKWISE. Exhaust: Carefully rotate COUNTERCLOCKWISE.

• Remove the pads (2) from the lifters. Use a small screwdriver and a magnetic rod for removal.Note pad numbers.

• Select the proper valve adjusting pad from the chart below:

|

Pad range |

Pad Availability: 25 increments |

|

No. 200 - 2.00mm (0.079 in) |

Pad stepped in 0.05 mm (0.002 in) increments |

NOTE:

Thickness of each pad is marked on the pad face that contacts the valve lifter (not the cam).

• Round off the hundredths digit of the original pad number to the nearest 0.05 mm increment.

|

Hundredths digit |

Rounded valve |

|

0 or 2 |

0 |

|

5 |

NOT ROUNDED OFF |

|

8 |

10 |

EXAMPLE:

Original pad number = 258 (2.58 mm)

Rounded off digit = 260

NOTE:

Pad can only be selected in 0.05 mm (0.002 in) increments.

Determine the required replacement pad thickness by one of the two following methods:

Shim calculation method:

Since all shims come in .05mm (.002") increments, you can quickly calculate the required size without a chart.

If the measured clearance is within 0.05mm (0.002") of the required clearance, then no change is needed.

If the measured clearance greater than 0.05mm (0.002") but 0.10mm (0.004") or less different than the required clearance then the next size shim is required.

If the measured clearance greater than 0.10mm (0.004") but 0.15mm (0.006") or less different than the required clearance then the next size shim is required.

Clearances that are too small require thinner shims. Clearances that are too large require thicker shims.

Example: Required exhaust valve clearance is 0.16~0.20mm. Measured clearance is 0.12mm (gap too small). Installed shim is Y270. Required shim is one size thinner: Y265.

Shim Chart Lookup Method:

• Locate the "Installed Pad Number" on the chart, and then find the measured valve clearance. The point where these coordinates intersect is the new pad number.

NOTE:

Use the new pad number as a guide only as the number must be verified.

Pad number verification steps:

• Install the new pad with the number down.

• Remove the adjusting tool.

• Recheck the valve clearance.

• If the clearance is incorrect, repeat all of the clearance adjustment steps until the proper clearance is obtained.

Assembly

1. Reverse removal steps.

NOTE:

Inspect the head cover gasket and replace it if damaged.

2. Tighten:

• Cylinder head cover bolts

• Fuel tank bolts

Head Cover Bolt:

10Nm(1.0mkg, 7.2 ftlb)

Fuel Tank Bolt:

10Nm(1.0rrvkg, 7.2 ftlb)

INTAKE

|

MEASURED |

INSTALLED PAD NUMBER |

||||||||||||||||||||||||

|

200 |

205 |

210 |

215 |

220 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|

|

0.00 - 0 05 |

200 |

205 |

210 |

215 |

220 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

||

|

0.06 - 0 10 |

200 |

205 |

210 |

215 |

220 |

225 |

230 |

235 |

240 |

240 |

260 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

|

|

0 11 - 0.15 |

|||||||||||||||||||||||||

|

0 16 - 0.20 |

205 |

210 |

215 |

220 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|

|

0.21 - 0.25 |

210 |

215 |

220 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

200 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||

|

0 26 - 0.30 |

215 |

220 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|||

|

0.31 - 0.35 |

220 |

22ft |

230 |

23ft |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||

|

0 36 - 0 40 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|||||

|

0 41 - 0 45 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||||

|

0.46 - 0 50 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|||||||

|

0 51 - 0.55 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||||||

|

0 56 - 0 60 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|||||||||

|

0.61 - 0.65 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||||||||

|

0 66 - 0.70 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|||||||||||

|

0.71 - 0.75 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||||||||||

|

0.76 - 0 80 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|

||||||||||||

|

0.81 - 0.85 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||||||||||||

|

0 86 - 0 90 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

VALVE CLEARANCE (cold): |

||||||||||||||

|

0.91 - 0.95 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||||||||||||||

|

0.96 - 1 00 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

0.11 to 0.15 mm (0.004 — 0.006 in) |

||||||||||||||||

|

1.01 - 1.05 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||||||||||||||||

|

1.06 - 1.10 |

295 |

300 |

305 |

310 |

315 |

320 |

Measured clearance is 0.32 mm (0.013 in) |

||||||||||||||||||

|

1.11 - 1.15 |

300 |

305 |

310 |

315 |

320 |

||||||||||||||||||||

|

1.16 - 1.20 |

305 |

310 |

315 |

320 |

Pad number : (example) |

||||||||||||||||||||

|

1 21 - 1 25 |

310 |

315 |

320 |

||||||||||||||||||||||

|

1 26 - 1 30 |

315 |

320 |

Pad No. 255 = 2.55 mm (0.100 in) |

||||||||||||||||||||||

|

1.31 - 1 35 |

320 |

||||||||||||||||||||||||

EXHAUST

|

MEASURED |

INSTALLED PAD NUMBER |

||||||||||||||||||||||||

|

200 |

205 |

210 |

215 |

220 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|

| 0.00 - 0 05 |

200 |

205 |

210 |

215 |

220 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

|||

|

0.06 - 0 10 |

200 |

205 |

210 |

216 |

220 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

||

|

0 11 - 0.15 |

200 |

205 |

210 |

215 |

220 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

|

|

0 16 - 0.20 |

|||||||||||||||||||||||||

|

0.21 - 0.25 |

205 |

210 |

215 |

220 |

225 |

230 |

235 |

240 |

246 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|

|

0 26 - 0.30 |

210 |

215 |

220 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||

|

0.31 - 0.35 |

216 |

220 |

225 |

230 |

235 |

240 |

24ft |

260 |

255 |

2ft0 |

20ft |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|||

|

0 36 - 0 40 |

220 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||

|

0 41 - 0 45 |

225 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

^70 |

2'5 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|||||

|

0.46 - 0 50 |

230 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|

|||||

|

0 51 - 0.55 |

235 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|||||||

|

0 56 - 0 60 |

240 |

245 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||||||

|

0.61 - 0.65 |

245 |

250 |

265 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|||||||||

|

0 66 - 0.70 |

250 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||||||||

|

0.71 - 0.75 |

255 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|||||||||||

|

0.76 - 0 80 |

260 |

265 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

||||||||||||

|

0.81 - 0.85 |

265 |

2 70 |

275 |

280 |

285 |

290 |

295 |

300 |

306 |

310 |

315 |

320 |

|||||||||||||

|

0 86 - 0 90 |

270 |

275 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

316 |

320 |

VALVE CLEARANCE (cold): |

|||||||||||||

|

0.91 - 0.95 |

276 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

316 |

320 |

|||||||||||||||

|

0.96 - 1 00 |

280 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

0.16 - 0.20 mm (0.006 - 0.008 in) |

|||||||||||||||

|

1.01 - 1.05 |

285 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

|||||||||||||||||

|

1.06 - 1. 10 |

290 |

295 |

300 |

305 |

310 |

315 |

320 |

Measured clearance is 0.32 mm (0.013 in) |

|||||||||||||||||

|

1. 11 - 1. 15 |

295 |

300 |

305 |

310 |

315 |

320 |

|||||||||||||||||||

|

1. 16 - 1. 20 |

300 |

305 |

310 |

315 |

320 |

Pad number : (example) |

|||||||||||||||||||

|

1 21 - 1 25 |

305 |

310 |

315 |

320 |

|||||||||||||||||||||

|

1 26 - 1 30 |

310 |

315 |

320 |

Pad No. 255 = 2.55 mm (0.100 in) |

|||||||||||||||||||||

|

1.31 - 1 35 |

320 |

||||||||||||||||||||||||

Spark Plug, Emmissions, Exhaust and Carburetor

Spark Plug, Emmissions, Exhaust and Carburetor

SPARK PLUG

1. Remove:

• Spark plug(s)

2. Inspect:

• Electrode (1) Wear/Damage — Replace.

• Insulator color (2)

3. Measure:

• Plug gap (3)

Use a Wire Gauge or Feeler Gauge. Out of specification — Regap.

0.7 ~ 0.8 mm (0.028 - 0.31 in)

Clean the plug with a spark plug cleaner if necessary-

Standard Spark Plug: BP8 ES (NGK) W24EP-U (NIPPONDENSO)

Before installing a spark plug, clean the gasket surface and plug surface.

4. Tighten:

• Spark plug(s)

20 Nm (2.0 mkg, 14ftlb)

NOTE:

Finger-tighten the spark plug(s) before torquing to specification.

CANISTER (For California Only)

This model is equipped with a canister to prevent the discharging of fuel vapor into the atmosphere.

1. Inspect:

• Hoses (1) (2) (5) Cracks/Damage — Replace. Clog - Clean.

• Canister (4) Cracks/Damage — Replace.

3 Carburetor [B] From fuel tank [C] To atmosphere

A EMISSION HOSE ROUTING

CRANKCASE VENTILATION SYSTEM

1. Inspect:

• Crankcase ventilation hose ® Cracks/Damage — Replace.

FUEL LINE

1. Inspect:

• Fuel hose (1)

• Vacuum hose (2) Cracks/Damage — Replace.

INTAKE MANIFOLD

1. Tighten:

• Carburetor clamps

• Carburetor joint bolts

2. Inspect:

• Carburetor joint

• Gaskets Cracks/Damage — Replace.

EXHAUST SYSTEM

1. Inspect:

• Exhaust pipe gasket(s) (1)

• Muffler clamp gasket(s) (2) Damage — Replace. Exhaust gas leakage — Repair.

2. Tighten:

• Exhaust pipe bolts

• Muffler bolts

Exhaust Pipe Flange (3) :

10 Nm (1.0 m-kg, 7.2ft-lb)

Exhaust Pipe Clamp (4) :

20 Nm (2.0 m-kg, 14ftlb)

Muffler Bracket (5) :

25 Nm (2.5 m-kg, 18 ft-lb)

Exhaust Chamber Mount (7) :

20 Nm (2.0 m-kg, 14 ft-lb)

Muffler Clamp (6) :

20 Nm (2.0 m-kg, 1 4 ft-lb)

IDLE SPEED/CARBURETOR SYNCHRONIZATION

IDLE SPEED

1. Adjust

• Idle speed

Warm up the engine and turn the throttle stop screw (1) to adjust.

Idle Speed

1,050 + 50 r/min

Carburetor Adjustment.

Carburetors must be adjusted to open and close simultaneously.

NOTE:

Valve clearance must be set properly before synchronizing the carburetors.

1. Remove:

• Seat

• Fuel tank

2. Disconnect:

• Vacuum plugs (1)

• Vacuum hose (2)

3. Install:

• Vacuum Gauge (YU-08030) (1)

• Suitable test fuel tank

4. Remove:

• Y.I.C.S. plug (2)

5. Attach:

• Y.I.C.S. shutoff tool (YM-08025) (3)

6. Start the engine and let it warm up.

7. Inspect:

• Idle speed

Out of specification — Turn throttle stop screw (1) to adjust.

Idle Speed

1,050 ±50 r/min

8. Adjust:

• Carburetor synchronization

Carburetor synchronization adjustment steps:

• Synchronize the carburetor No. 1 to the carburetor No. 2 by turning the synchronizing screw (1) until the both gauge readings are the same.

• Rev. the engine for a fraction of a second, two or three times, and check the synchronization again.

Vacuum Pressure at Idle Speed:

23.99 kPa (180 mm Hg, 7.09 in Hg)

Vacuum Synchronous Difference:

0.67 kPa (5 mm Hg, 0.2 in Hg)

• Repeat the above steps to synchronize the carburetor No. 4 to the carburetor No. 3 by turning the synchronizing screw (3) until the both gauge readings are the same.

• Repeat the same steps to synchronize No. 3 carburetor to No. 1 carburetor, then turn synchronizing screw (2) until both gauge readings are the same.

Engine Oil

Engine Oil

At 5°C (40°F) or Higher:

SAE 20W40 Type SE Motor Oil

At 15°C (60°F) or Lower:

SAE 10W30 Type SE Motor Oil

NOTE:

Recommended engine oil classification; API Service "SE", "SF" type or equivalent (e.g. "SF-SE", "SF-SE-CC", "SF-SE-SD" etc.)

Oil Level Measurement

1. Check

• Oil level

Oil level low — Add sufficient oil.

Oil level visual inspection steps:

• Place the motorcycle on its center stand and warm up the engine for several minutes.

NOTE:

Position the motorcycle straight up when checking oil level, a slight tilt to the side can produce false readings.

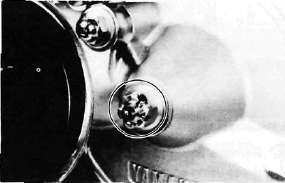

• Stop the engine and visually check the oil level through the level window (1).

(2) Maximum (3) Minimum

Oil Change (Without filter)

1. Warm up the engine for several minutes, then place a receptacle under the engine.

2. Remove:

• Oil filler cap

3. Remove:

• Engine drain plug (1)

4. Tighten:

• Drain plug

Engine Drain Plug:

43 Nm (4.3 m-kg, 31 ft-lb)

5. Fill:

• Crankcase

Engine Oil

2.5 L (2.2 imp qt, 2.6 US qt)

CAUTION:

Do not allow foreign material to enter the crankcase.

6. Install:

• Filler cap

Oil Change (With filter)

1. Warm up the engine and place a receptacle under the engine.

2. Remove:

• Oil filler cap

• Drain plug

Drain the engine oil.

3. Remove:

• Oil filter bolt (1)

• Filter cover (2)

4. Tighten:

• Drain plug

Engine Drain Plug:

43 Nm (4.3 m-kg, 31 ft-lb)

5. Install:

• Oil filter bolt (1)

• Spring (2)

• Washer (3)

• Oil filter (New) (4)

• O-ring (5)

• Oil filter assembly

• Be sure the O-ring (5) is positioned properly.

• Fit the filter cover projection into the crank-case cover slot.

6. Tighten:

• Oil filter bolt

Oil Filter Bolt:

15 Nm (1.5 mkg, 11 ftlb)

7. Fill:

• Crankcase

Engine Oil:

2.8 L (2,5 imp qt, 3.0 US qt)

8. Install:

• Oil filler cap

9. Warm up the engine and check for oil leaks. Stop the engine instantly if leaking occurs.

Leaks — Check cause.

10. Check:

• Oil level

Level low — Add sufficient oil.

Clutch, Timing and Compression

Clutch, Timing and CompressionCLUTCH ADJUSTMENT

1. Loosen:

• Adjuster locknut (1)

2. Adjust:

• Clutch lever free play (3)

(by turning adjuster (2) in or out)

Free play:

2-3 mm (0.08 - 0.12 in)

If free play can not be adjusted, adjust by clutch cable length adjuster.

3. Loosen:

• Adjuster locknut (1)

4. Adjust:

• Clutch lever free play

(by turning clutch cable length adjuster (2) )

IGNITION TIMING CHECK

Flywheel is marked as follows:

(1) TDC for No. 1 cylinder

(2) Firing range for the No. 1 cylinder

1. Check:

• Ignition timing

Ignition timing check steps:

• Remove the cover.

• Connect the Timing Light (YM-33277) i to No. 1 cylinder spark plug lead.

• Warm up the engine and let it idle at the specified idle speed of 1,050 ± 50 r/min.

• Visually check the stationary pointer in the timing window to verify it is within the required firing range indicated on the flywheel.

Incorrect firing — Check timing plate and/or pickup assembly (tightness damage)

Refer to CHAPTER 6, "ELECTRICAL" for further information.

(1) TDC for No. 1 cylinder

(2) Firing range for the No. 1 cylinder

COMPRESSION PRESSURE MEASUREMENT

NOTE:

Insufficient compression pressure will result in performance loss.

1. Measure:

• Valve clearance

Out of specification — Adjust.

2. Warm up the engine.

3. Remove:

• Spark plugs

Compression pressure measurement steps:

• Install the Compression Gauge (YU-33223) (1) using an adapter.

• Crank over the engine with the electric starter (be sure the battery is fully charged) with the throttle wide-open until the compression reading on the gauge stabilizes.

• Check readings with specified levels (See chart).

Compression Pressure (at sea level):

Standard: 1,078 kPa (11 kg/cm2, 156 psi)

Minimum: 882 kPa (9 kg/cm2, 128 psi)

Maximum: 1,176 kPa (12 kg/cm2, 171 psi)

When cranking the engine, ground all of the spark plug leads to prevent sparking.

• Repeat the previous steps for the other cylinders.

• If pressure falls below the minimum level:

1. Squirt a few drops of oil into the affected cylinder.

2. Measure the compression again.

|

Compression Pressure (with oil introduced into cylinder) |

|

|

Higher than without oil |

Worn or damaged pistons |

|

Same as without oil |

Defective ring(s). valves, cylinder head gasket or piston is possible. |

|

Above maximum level |

Inspect cylinder head, valve surfaces, or piston crown for carbon deposits. |

NOTE:

The difference between the highest and lowest cylinder compression readings must not vary more than the specified value.

Difference Between Each Cylinder:

Less than 98 kPa (1 kg/cm2,14 psi)

Chassis Maintenance

Chassis Maintenance

FINAL GEAR OIL

Oil Level Measurement

1. Place the motorcycle on a level area and place on its centerstand.

2 Remove:

• Oil filler cap

3. Observe:

• Oil level (2)

Low level— Add oil. (1) Oil

NOTE:

Oil level must be up to the brim of the filler hole.

CAUTION:

Be sure that no foreign material enters the final gear case.

Gear Oil Replacement

1. Place a receptacle under the final gear case.

2. Remove:

• Filler cap

• Drain plug (1) Drain final gear oil.

3. Install:

• Drain plug

23 Nm (2.3 m-kg, 17ftlb)

4. Fill

• Gear case (to specified level.)

Final Gear oil:

SAE80 API "GL-4" Hypoid

gear oil Oil Capacity:

0.20 / (0.18 imp qt, 0.21 qt)

NOTE:

If desired, an SAE 80W90 Hypoid gear oil may be used for all conditions.

5. Install:

• Filler cap

23 Nm (2.3 m-kg, 17 ft-lb)

AIR FILTER

1. Remove:

• Seat

• Fuel tank

• Rubber cover

2. Remove:

• Air filter cover (1)

3. Eliminate:

• Dust

Use compressed air

4. Inspect:

• Element Damage - Replace.

CAUTION:

The engine should never be run without the air/filter element installed; excessive piston and/or cylinder wear may result.

5. Install:

• Element

CAUTION:

Make sure the element cover fits into the corresponding filter case edge.

FRONT BRAKE

Brake Fluid Inspection

1. Check:

• Brake fluid level

Level low — Replenish.

NOTE:

Use only a designated, quality fluid.

DOT NO. 3

NOTE:

Be sure that:

• Water does not enter the master cylinder when refilling.

• Spilled fluid is cleaned up immediately to prevent painted surfaces or plastic parts from eroding.

(1) Lower level

FRONT BRAKE/REAR BRAKE

Front Brake Lever Free Play Adjustment

1. Loosen:

• Adjuster lockout (1)

2. Adjust:

• Free play (3)

Turn the adjuster (2) until the free play (3) is within the specified limits.

Brake Lever Free Play:

2-5 mm (0.08 ~ 0.2 in)

CAUTION:

Proper level free play is essential to avoid excessive brake drag.

3. Tighten:

• Adjuster locknut

Brake Pad Inspection

1. Activate the brake lever

2. Inspect:

• Wear indicator (1) Indicator almost contacts disc (2) — Replace pads. Refer to CHAPTER 5, "CHASSIS."

REAR BRAKE

Rear Brake Pedal Height Adjustment

1. Loosen:

• Adjust locknut (1) .

2. Adjust:

• Brake pedal height (2).

Turn the adjuster (3) until the brake pedal position is at the specified height.

Brake Pedal Height: 10 mm (0.4 in) Below the Top of the Footrest

Adjust pedal height, then adjust brake pedal free play.

REAR BRAKE

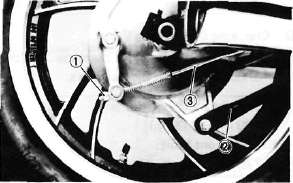

Rear Brake Shoe Inspection

1. Depress brake pedal

2. Inspect:

• Wear indicator (2)

Indicator at wear limit line — Replace brake shoes.

(1) Wear limit line

Rear Brake Pedal Free Play Adjustment

1. Rotate:

• Adjuster nut (1)

Turn it clockwise or counterclockwise until proper brake pedal free play is attained.

Brake Pedal Free Play:

20-30 mm (0.8 -1.2 in)

Check to verify correct brake light operation after adjustment.

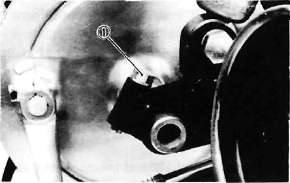

Brake Light Switch Adjustment

1. Hold the switch body (1) with your hand so that it does not rotate and turn the adjusting nut (2) .

CABLE INSPECTION AND LUBRICATION

Cable inspection and lubrication steps:

• Remove the two screws that secure throttle housing to handlebar.

• Hold cable end high and apply several drops of lubricant to cable.

• Coat metal surface of disassembled throttle twist grip with suitable all-purpose grease to minimize friction.

• Check for damage to cable insulation. Replace any corroded or obstructed cables.

• Lubricate any cables that do not operate smoothly.

SAE 10W30 Motor Oil

BRAKE AND CHANGE PEDALS/ BRAKE CLUTCH LEVERS

Lubricate pivoting parts of each lever and pedal.

CENTERSTAND AND SIDESTAND

Lubricate centerstand and sidestand at their pivot points.

SAE 10W30 Motor Oil

FRONT FORK OIL CHANGE

Securely support the motorcycle so there is no danger of it falling over.

1. Place a suitable stand under the engine to raise the front wheel off the ground.

2. Loosen:

• Inner tube pinch bolt (1)

3. Remove:

• Fork cap (2)

• Cap bolt (3)

Use the Front Fork Cap Socket (YM-01104) (4)

4. Remove:

• Drain screw (1) Drain the fork oil.

Do not allow any oil to contact the disc brake components. If oil is discovered, be sure to remove it, otherwise diminished braking capacity and damage to the rubber components of the brake assembly will occur.

7. Inspect:

• O-ring (1) (Cap-bolt)

• Gasket (Drain screw) Wear/Damage — Replace.

8. Install:

• Drain screw

9. Fill:

• Front fork

Each Fork:

383cm3(13.51 impoz, 12.95 USoz)

After filling pump the forks slowly up and down to distribute the oil.

10. Tighten:

• Cap-bolt

• Pinch bolt

Cap Bolt: 23 Nm (2.3 rrvkg, 17ftlb)

Pinch Bolt: 20 Nm (2.0 mkg, 14ft-lb)

11. Install:

• Fork cap

REAR SHOCK ABSORBER ADJUSTMENT

If the spring seat is raised, the spring becomes stiffer, and if lowered, it becomes softer.

Standard Position: B A. — Softest (1) E. — Stiffest (2)

Always adjust each shock absorber to the same setting. Uneven adjustment can cause poor handling and loss of stability.

STEERING HEAD ADJUSTMENT

Steering Head Inspection

1. Place the motorcycle on its centerstand, then elevate the front wheel.

2. Check:

• Steering assembly bearings

Grasp the bottom of the forks and gently rock the fork assembly back and forth. Looseness — Adjust.

Adjustment

Steering head adjustment steps:

• Remove the handlebar securing bolts (1)

• Remove the handlebars .

• Remove the steering stem nut (2)

• Loosen the pinch bolts (3) .

• Remove the steering crown (4) .

• Remove the lock washer (5) .

• Loosen the ring nut (6) ,

• Tighten the ring nut (7) .

Ring Nut (Lower):

50 Nm (5.0 m-kg, 36 ft-lb)

The tapered side of ring nuts must face downward.

• Loosen the ring nut (7) completely and retighten it to specification.

Ring Nut (Lower):

6Nm(0.6 m-kg,4.3ft-lb)

• Check the steering stem by turning it lock to lock. If there is any binding, remove the steering stem assembly and inspect the steering bearings 8 .

(See CHAPTER 5, STEERING HEAD for more details.)

• Hand-tighten the ring nut (6) , then align the slots of both ring nuts. If not aligned, hold the lower ring nut (7) and tighten the other until they are aligned.

• Install the lock washer (5) .

NOTE:

Make sure the lock washer tab is placed in the slots.

• Install the steering crown (4) and tighten the steering stem nut (2) to specification.

Steering Stem Nut:

110 Nm (11.0 m-kg, 80 ft*]

• Install the handlebar and torque the bolt 0 to specification.

Pinch Bolt: 20Nm(2.0m-kg, 14ft-lb)

Handlebar Bolt: 20 Nm (2.0 m-kg, 14 ft-lb)

WHEEL BEARINGS

Front Wheel Bearings

1. Raise the front end of the motorcycle, and spin the wheel by hand. Touch the axle or front fork while spinning the wheel-Excessive vibration — Replace bearings.

Rear Wheel Bearings

1. Remove:

• Rear wheel

2. Check:

• Bearing movement Rotate with the fingers. Roughness/Wear — Replace.

TUBELESS TIRES AND ALUMINUM WHEELS

• Always inspect aluminum wheels before a ride.

• Place the motorcycle on its centerstand and check for cracks, bends, or warpage of the wheels.

• Do not attempt any repairs to the wheel; replace any defective wheel.

• Do not attempt to use tubeless tires on a wheel designed for use with tube-type tire only. Tire failure and subsequent personal injury may result from sudden deflation.

• Be sure to install the proper tube when using tube-type tires.

• New tires have a relatively poor adhesion on the road surface so do not allow them to be subjected to high speed load from maximum speed until after a break-in run of approx. 100 km (60 mi).

• Always use the correct tire inflation pressure acording to the operating conditions.

|

Wheel |

Tire |

|

Tube type |

Tube type only |

|

Tubeless |

Tube type or tubeless |

|

A Tire |

C Tubeless tire |

|

B Wheel |

D Tube type tire |

(1) Air valve

(2) Aluminum wheel (Tubeless type)

(3) Tube

(4) Aluminum wheel (tube type)

Always perform the following steps to ensure safe operation, maximum tire performance, and long service. 1. Measure:

• Tire pressure Out of specification — Adjust.

|

Basic weight: With oil and full fuel tank |

224 kg (494 lb) |

|

|

Maximum load * |

246 kg |

542 lb) |

|

Cold tire pressure |

Front |

Rear |

|

Upto90kg(198lb) load" |

177 kPa (1.8 kg/cm2. 26 psi) |

196 kPa (2.0 kg/cm2. 28 psi) |

|

90 kg (198 lb) load ~ 246 kg (542 lb) load- |

196 kPa (2.0 kg/cm*, 28 psi) |

275 kPa (2.8 kg/cm2. 40 psi) |

|

High speed riding |

206 kPa (2.1 kg/cm? 30 psi) |

225 kPa (2.3 kg/cm2 32 psi) |

* Load is the total weight of cargo, rider, passenger, and accessories.

2. Inspect:

• Tire surfaces Wear/Damage — Replace.

Minimum Tire Tread Depth: (Front and Rear) 1.0 mm (0.04 in)

(1) Tread depth

(2) Side wall

(3) Wear indicator

3. Inspect:

• Aluminum wheels

Damage/Bends — Replace. Never attempt even small repairs to the wheel.

NOTE:

Always balance the wheel when a tire or wheel has been changed or replace.

Ride conservatively after installing a tire to allow it to seat itself properly on the rim.

Chapter 3, ENGINE OVERHAULING

Chapter 3, ENGINE OVERHAULINGCHAPTER3. ENGINEOVERHAULING

Engine Removal

Engine RemovalENGINE REMOVAL

NOTE:

It is not necessary to remove the engine in order to remove the following components:

• Piston

• Clutch

• Carburetor

• Oil pump

PREPARATION FOR REMOVAL

1. Remove all dirt, mud, dust, and foreign material before removal and disassembly.

2. Use proper tools and cleaning equipment. Refer to CHAPTER 1, "SPECIAL TOOL"

NOTE:

When disassembling the engine, keep mated parts together. This includes gear, cylinders, pistons, and other parts that have been "mated" through normal wear. Mated parts must be reused as an assembly or replaced.

3. During the engine disassembly, clean all parts and place them in trays in the order of disassembly. This will speed up assembly time and help assure that all parts are correctly reinstalled in the engine.

SEAT AND FUEL TANK

1. Remove:

• Seat (1)

• Fuel tank (2)

• Left side cover (3)

2. Drain:

• Engine oil

BATTERY

1. Disconnect:

• Battery leads (1),(2)

• Breather hose (3)

NOTE:

Disconnect the negative lead first.

EXHAUST PIPE AND MUFFLER

1. Remove:

• Nuts

2. Loosen:

• Clamp bolts

3. Remove:

• Exhaust pipes (1)

4. Remove:

• Chamber mount bolt (1)

• Muffler mount bolts (2)

• Muffler with chamber

CARBURETOR AND CABLES

1. Loosen:

• Clamp screws

2. Remove:

• Air cleaner case (1) mount bolts (2)

3. Push the air cleaner case toward the rear to disconnect air outlet hoses from carburetors.

4. Disconnect:

• Choke cables (3)

5. Remove:

• Carburetors

• Throttle cable (4)

NOTE:

After removing the carburetors, cover the carburetors with a clean cloth to keep dust and dirt out.

7. Disconnect:

• Crankcase ventilation hose (1) (from crankcase)

• Clutch cable (2)

CONNECTOR

1. Remove:

• Plate

2. Disconnect:

• Pickup coil lead

• Generator lead

• Neutral switch lead

• Oil level switch lead

• Starter motor lead (1) (from starter motor)

SHIFT PEDAL BRAKE PEDAL, FOOTREST AND DRIVE SHAFT

1. Remove:

• Shift pedal (1)

• Left footrest (2)

2. Disconnect:

• Rubber boot (3)

3. Remove:

• Joint bolts (4)

4. Remove:

• Brake pedal (1)

• Right footrest (2)

ENGINE REMOVAL

1. Place a suitable stand under the engine.

2. Remove:

• Mounting bolts

• Downtube frame (1)

3. Remove:

• Engine assembly (from chassis right side)

Cylinder Head Removal

Cylinder Head RemovalENGINE OVERHAUL

A. Cylinder Head and Cylinder

1. Remove the cylinder head cover.

2. Remove the left crankcase cover (pickup coil cover).

3. Remove the cam chain tensioner.

4. Use a 19 mm wrench on the timing plate flats to rotate the crankshaft counterclockwise until the engine is at T.D.C.

CAUTION:

Never use an alien wrench to rotate the crankshaft. Always use the 19 mm flats provided on the timing plate to rotate this engine.

5. Remove the four cam sprocket bolts.

6. Slip each sprocket off its mounting boss on the cam.

CAUTION:

From this point on, do not rotate the cam shaft or valve damage may occur. On this, it is not necessary to break the cam chain. However, it can be broken if so desired. It is easier to disassemble the engine without separating the chain.

7. Remove the cam chain guide.

1. Cam chain guide

8. Remove the cam caps. Note the location of the cam caps. The caps for the intake cam shaft are identified 1-1 through I-3. The exhaust cam caps are identified E-1 through E-3. Directional arrows are cast on each cap and point toward the clutch side.

9. Fasten safety wire to the cam chain to prevent its falling into the crankcase cavity.

Slide the cams and sprockets from under the chain and remove the cams and sprockets.

10. Remove the front cam chain guide.

1. Front cam chain guide

11. Remove the spark plugs.

12. Remove the cylinder head bolts and nuts in the numerical order as shown. Start by loosening each nut 1/2 turn until all of the nuts are loose. Remove the cylinder head.

Cylinder and Cylinder Head Disassembly

Cylinder and Cylinder Head Disassembly

13. Remove the front cylinder holding nut and remove the cylinder assembly. It may be necessary to tap the cylinder lightly to loosen it from the base gasket.

14. Remove the rear cam chain guide by loosening the holding bolt.

1. Holding bolt 2. Rear cam chain guide

B. Cylinder Head Disassembly

1. Remove the valve lifters and pads. Be careful not to scratch the lifter bodies or lifter bores in the cylinder head. Be very careful to identify each lifters position so that it may be returned to its original place.

1. Valve filter 2. Adjusting pad

2. Mount the valve spring compressor on the head and depress each valve spring. Take out the retainer and valve spring with tweezers.

1. Valve spring compressor

3. Remove valves.

NOTE:

Deburr any deformed valve stem end. Use an oil stone to smooth the stem end. This will help prevent damage to the valve guide during valve removal.

4. Use a small box to hold the parts and identify the original position of each lifter and valve. Be very careful not to mix the location of these components.

Piston, Pickup Coil, Shifter, Starter, Generator and Clutch Removal

Piston, Pickup Coil, Shifter, Starter, Generator and Clutch RemovalC. Piston

1. Mark each piston to aid in reassembly.

2. Place a clean towel or rag into the crank-case to keep circlips and material from falling into the engine.

3. Remove piston pin clips, piston pins, and pistons.

D. Pick-up Coil Assembly

1. Remove the alien bolt that holds the timing plate.

2. Remove the pick-up coil securing screws and remove the pick-up coil assembly.

E. Shifter

1. Remove the change pedal.

2. Remove the left crankcase cover.

3. Remove the shift lever assembly and shift shaft assembly.

1. Shift lever assembly 2. Shift shaft assembly

4. Remove the middle gear case oil level maintaining plug.

F. Starter Motor and Generator

1. Remove the starter motor securing bolts and remove the motor assembly.

2. Remove the generator cover and stator coil assembly.

3. Install the rotor holding tool (special tool) on the rotor as shown and remove the rotor holding bolt.

1. Rotor holding tool

4. Invert the holding tool as shown and insert the rotor puller adapter (special tool) into the rotor shaft and screw in the rotor puller (special tool). Remove the rotor.

1. Rotor puller adapter

G. Clutch

1. Remove right crankcase cover.

2. Release the tension evenly on the 6 mm bolts and remove the clutch pressure plate and clutch springs.

NOTE:

The outermost friction plate has a tab with a V-cut (1) in it. Give some identifying mark to the corresponding dog (2) in the clutch housing. This dog is the narrowest.

3. Remove the friction plates and clutch plates.

(1) Clutch spring bolts

(2) Clutch springs

(3) Pressure plate

(4) Friction plates

(5) Clutch plates

4. Straighten the lock washer tab. Use the clutch boss holder (special tool) to hold the clutch boss and remove the lock nut and lock washer.

1. Clutch boss holder

5. Remove the clutch boss and spacer.

6. Screw in a suitable length of 6 mm bolt into the one of the threaded holes on the collar and pull out the collar and needle bearing from the primary driven gear.

1. Collar

7. Remove the primary driven gear assembly and oil pump drive sprocket.

Oil Pump and Middle Gear Disassembly

Oil Pump and Middle Gear DisassemblyH. Oil Pump Removal and Disassembly

1. Remove the strainer cover. Note the wire harness clip position.

2a. Remove the oil pump securing bolts and remove the sprocket cover and oil pump assembly.

2b. Remove the Oil pump drive sprocket (1), Chain (2) Collar (3) and thrust plate.

CAUTION:

Do not attempt to remove the strainer screen as it is permanently fitted onto the pump housing. If the pump housing and/or any parts of the pump are damaged, the pump assembly must be replaced with a new one.

3. Remove the oil pump driven sprocket.

4. Remove the oil pump cover and rotor assembly.

5. Remove the pressure relief valve spring and plunger.

I. Middle Gear

1. Remove the middle driven gear housing holding bolts.

2. Remove the middle driven gear housing assembly and shims.

NOTE:

If it is difficult to remove housing assembly, loosen the two crankcase bolts located near the middle driven gear housing.

3. Remove "TORX" screws holding the middle drive gear assembly.

4. Remove the bearing retainers.

Upper Crankcase Disassembly

Upper Crankcase DisassemblyJ. Crankcase Disassembly

1. Remove the upper crankcase bolts, starting the highest numbered bolt. Turn over the engine and remove the lower crankcase bolts,

CRANKCASE TORQUE SEQUENCE

UPPER CASE

LOWERCASE

2. Separate the lower case from the engine. Use a soft rubber hammer to carefully separate the crankcase.

K. Upper Crankcase

1. Remove the middle drive gear and damper assembly.

2. Remove the transmission main shaft assembly.

3. Remove the A.C.G. shaft cover.

4, Remove the oil spray nozzle.

5. Carefully remove the A.C.G. shaft from the gear.

6. Remove the gear from the chain.

7. Straighten the lock washer tube and remove the bolt securing the starter idle gear shaft. Remove the shaft and starter idle gear.

Lower Crankcase Disassembly

Lower Crankcase DisassemblyL. Lower Crankcase

1. Remove the dowel pin and "O-ring".

2. Remove the shift fork guide bar and shift forks. The shift forks are identified by numbers cast on their sides.

3. Remove the bolt securing the shift cam locating pin and remove the stopper plate and locating pin.

4. Remove the neutral switch.

1. Shift cam locating pin 2. Neutral switch

5. Pull out the shift cam.

6. Remove the driven shaft bearing cover holding screws and remove the bearing cover.

7. Remove the bearing and 5th wheel gear from the driven shaft and pull out the driven shaft assembly.

1. 5th wheel gear

Cylinder Head and Valves -- Inspection & Repair

Cylinder Head and Valves -- Inspection & RepairINSPECTION AND REPAIR

A. Cylinder Head Cover

Place head cover on a surface plate. There should be no warpage. Correct by re-surfacing as follows:

Place #400 or #600 grit wet sandpaper on surface plate and re-surface head cover using a figure-eight sanding pattern. Rotate head cover several times to avoid removing too much material from one side.

B. Cylinder Head

1. Using a rounded scraper, remove carbon deposits from combustion chamber. Take care to avoid damaging spark plug threads and valve seats. Do not use a sharp instrument. Avoid scratching the aluminum.

2. Check the cylinder head warpage with a straight edge as shown.

The warpage should not exceed the specified limit, if necessary resurface. If the warpage exceeds allowable limit, the cylinder head should be replaced with a new one.

Cylinder head warpage: less than 0.03 mm (0.0012 in)

Allowable limit: 0.25 mm (0.010 in)

C. Valve, Valve Guide, and Valve Seat

1a. Check the valve face and the stem end for wear. If the valve face and/or the stem end are pitted or worn, regrind the valve with a valve refacer. Replace the valve if any dimension exceeds the specifications:

(1) 0.7 mm (0.028 in) Minimum Thickness (service limit)

(2) 0.5mm (0.020 in) bevel

(3) 4.0mm (0.157 in) Minimum Length (Service limit)

1b. Measure the contacting mark position on the valve face (1) and verify it is 0.3 mm (0.12 in) from the edge and 1.0mm +/- 0.1mm (0.039 +/- 0.004 in) wide. If it is out of range, the valve seat should be recut as detailed below.

2. Valve stem wear must be measured and then combined with valve guide measurements to guide clearance. This clearance must be within tolerances. If it exceeds the maximum limit, then replace either or both valve and guide, as necessary.

|

|

Valve Stem Clearance |

Maximum |

|

Intake |

0.010 — 0.037 mm (0.0004-0.0015 in) |

0.10 mm (0.004 in) |

|

Exhaust |

0.025-0.052 mm (0.0010-0.0020 in) |

0.12 mm (0.005 in) |

3. Valve stem end

Inspect the end of the valve stem. If the end appears to be "mushroomed" or has a larger diameter than the rest of the stem, the valve, valve guide, and oil seal should be replaced.

4. Turn valve on "V" blocks and measure the amount of stem runout with a dial gauge. If it exceeds the maximum limit, replace the valve.

Maximum valve stem runout: 0.03 mm (0.0012 in)

5. Valve guide and valve oil seal replacement If oil leaks into the cylinder through a valve due to a worn valve guide, or if a valve is replaced, the valve guide should also be replaced.

NOTE:

The valve oil seal should be replaced whenever a valve is removed or replaced.

a. Measure valve guide inside diameter with a small bore gauge. If it exceeds the limit, replace with an oversize valve guide.

Guide diameter (I.D.):

Limit: 7.10 mm (0.280 in)

b. To ease guide removal and reinstallation, and to maintain the correct interference fit, heat the head to 100t (212°F). Use an oven to avoid any possibility of head warpage due to uneven heating.

c. Use the appropriate shouldered punch (special tool) to drive the old guide out and drive the new guide in.

NOTE:

When a valve guide is replaced, the O-ring should also be replaced.

1. Valve guide remover 2. Valve guide installer

d. After installing the valve guide, use the 7 mm reamer (special tool) to obtain the proper valve guide to valve stem clearance.

e. After installing the valve guide in the cylinder head, the valve seat must be recut. The valve should be lapped to the new seat.

6. Grinding the Valve Seat

a. The valve seat is subject to severe wear. Whenever the valve is replaced or the valve face is re-surfaced (see caution) the valve seat should be re-surfaced at a 45° angle. If a new valve guide has been installed the valve seat must be recut to guarantee complete sealing between the valve face and seat.

CAUTION:

If the valve seat is obviously pitted or worn, it should be cleaned with a valve seat cutter. Use the 45° cutter, and when twisting the cutter, keep an even downward pressure to prevent chatter marks.

If cutting section "A" of the valve seat, use 30° cutter. If cutting section "B", use the 45° cutter. If cutting section "C" use 60° cutter. b. Measure valve seat width. Apply mechanic's bluing dye (such as Dykem) to the valve face and valve seat, apply a very small amount of fine grinding compound around the surface of the valve face insert the valve into position, and spin the valve quickly back and forth. Lift the valve, clean off all grinding compound, and check valve seat width. The valve seat and valve face will have removed bluing wherever they contacted each other. Measure the seat width with vernier calipers. It should measure approximately 1.1 mm (0.0433 in). Also, the seat should be uniform in contact area. If valve seat width varies, or if pits still exist, further cutting will be necessary. Remove just enough material to achieve a satisfactory seat.

|

|

Standard Width |

Wear Limit |

|

Seat width |

1.0 ±0.1 mm (0.0394 ± 0.0039in) |

1.4 mm (0.055 in) |

a. Seat width

c. If the valve seat is uniform around the perimeter of the valve face, but is too wide or not centered on the valve face, it must be altered. Use either the 30°, 45° or 60° cutters to correct the improper

seat location in the manner described below:

1) If the valve face shows that the valve seat is centered on the valve face, but too wide, then lightly use both the 30° and the 60° cutters to reduce the seat width to 1.1 mm (0.0433 in).

1. Valve seat cutter

2) If the seat shows to be in the middle of the valve face, but too narrow, use the 45°cutter until the width equals 1.1 mm(0.0433 in).

3) If the seat is too narrow and right up near the valve margin, then first use the 30° cutter and then the 45° cutter to get the correct seat width.

4) If the seat is too narrow and down near the bottom edge of the valve face, then first use the 60° cutter and then the 45° cutter.

7. Lapping the valve/valve seat assembly a. The valve/valve seat assembly should be lapped if neither the seat nor the valve face are severely worn.

b. Apply asmall amount of coarse lapping compound to valve face. Insert the valve into the head. Rotate the valve until the valve and valve seat are evenly polished. Clean off the coarse compound, then follow the same procedure with fine compound.

Continue lapping until the valve face shows a complete and smooth surface all the way around. Clean off the compound material. Apply bluing dye to the valve face and seat and rotate the valve face for full seat contact which is indicated by a grey surface all around the valve face where the bluing has been rubbed away.

c. Valve leakage check

After all work has been performed on the valve and valve seat, and all head parts have been assembled, check for proper valve/valve seat sealing by pouring solvent into each of the intake ports, then the exhaust ports. There should be no leakage past the seat. If fluid leaks, disassemble and continue to lap with fine lapping compound. Clean all parts thoroughly, reassemble and check again with solvent. Repeat this procedure as often as necessary to obtain a satisfactory seal.

Valve Springs and Lifters, Camshafts, Chain and Guides -- Inspection and Repair

Valve Springs and Lifters, Camshafts, Chain and Guides -- Inspection and RepairD. Valve Spring and Lifters

1. Checking the valve springs

a. This engine uses two springs of different sizes to prevent valve float or surging. The valve spring specifications show the basic value characteristics.

b. Even though the spring is constructed of durable spring steel, it gradually loses some of it's tension. This is evidenced by a gradual shortening of free length. Use a vernier caliper to measure spring free length. If the free length of any spring has decreased more than 2 mm (0.080 in) from its specification replace it.

c. Another symptom of a fatigued spring is insufficient spring pressure when compressed. This can be checked using a valve spring compression rate gauge. Test each spring individually. Place it in the gauge and compress the spring first to the specified compressed length with the valve closed (all spring specifications can be found in the previous section, Valve Spring), then to the length with the valve open. Note the poundage indicated on the scale at each setting. Use this procedure with the outer springs, then the inner springs.

NOTE:

All valve springs must be installed with larger pitch upward as shown.

|

Valve Spring Specifications |

||

|

|

OUTER |

INNER |

|

Free length |

37.0 mm (1.457 in) |

33.5 mm (1.319 in) |

|

Installed length (valve closed) |

34.0 mm (1.339 in) |

31.0 mm (1.220 in) |

|

Installed pressure |

17.2 kg -21.0 (37.9 - 46.3 lb) |

8.1 - 9.9 kg (17.9 - 21.8 1b) |

|

Allowable tilt from vertical |

1.6° |

|

2. Valve lifter

a. Check each valve lifter for scratches or other damage. If the lifter is damaged in any way, the cylinder head surface in which it rides is probably also damaged. If the damage is severe, it may be necessary to replace both the lifter and the cylinder head.

NOTE:

For proper valve lifter-to-head clearance, always install lifters on their original valves.

E. Camshafts, Cam chain and Cam Sprockets

1. Camshaft

a. The cam lobe metal surface may have a blue discoloration due to excessive friction. The metal surface could also start to flake off or become pitted.

b. If any of the above wear conditions are readily visible, the camshaft should be replaced.

c. Even though the cam lobe surface appears to be in satisfactory condition, the lobes should be measured with a micrometer. Cam lobe wear can occur without scarring the surface. If this wear exceeds a pre-determined amount, valve timing and lift are affected. Replace the camshaft if wear exceeds the limits.

| Cam Lobe A | Cam Lobe B | |

| Intake | 36.8 mm (1.449 in) | 28.1 mm (1.106 in) |

| Exhaust | 36.3 mm (1.429 in) | 28.06 mm (1.105 in) |

d. Install the camshaft on the cylinder head. Place a strip of Plastigage between camshaft and camshaft cap as illustrated (lengthwise along camshaft). Tighten the nuts with specified torque. Remove the camshaft cap and determine the clearance by measuring the width of the flattened Plastigage.

Cap nut tightening torque: 1.0m-kg(7.2ft-lb)

1. Plastigage

NOTE:

Do not turn camshaft when measuring clearance with Plastigage.

Camshaft-to-cap clearance:

|

Standard: |

0.020-0.054 mm |

|

|

(0.0008- 0.0021 in) |

|

Maximum: |

0.160 mm (0.006 in) |

If the camshaft-to-cap clearance exceeds specification, measure camshaft bearing surface diameter.

Bearing surface diameter:

|

Standard: |

24.967-24.980 mm |

|

|

(0.9830-0.9835 in) |

1) If camshaft diameter is less than specification, causing excessive clearance, replace camshaft.

2) If camshaft is within specification and camshaft-to-cap clearance is excessive, replace cylinder head.

2. Cam chain

Except in cases of oil starvation, the cam chain wears very little. If the cam chain has stretched excessively and it is difficult to keep the proper cam chain tension, the chain should be replaced.

3. Cam sprockets

Check cam sprockets for obvious wear.

4, Cam chain dampers

Inspect the top cam chain damper (stopper guide) and two (2) vertical (slipper-type) dampers for excessive wear. Any that shows excessive wear should be replaced. Worn dampers may indicate an improperly adjusted or worn-out cam chain.

(1) Upper guide

(2) Front guide

(3) Rear guide

5 Automatic Cam Chain Tensioner

Ensure operation is one-way and smooth. Inspect all parts for wear or damage

(1) End plug

(2) Washer

(3) Springs

(4) Tensioner body

(5) One way cam

(6) Tensioner rod

Cylinder and Piston -- Inspection and Repair

Cylinder and Piston -- Inspection and Repair. Cylinder

1. Inspect the cylinder walls for scratches. If vertical scratches are evident, the cylinder wall should be rebored or the cylinder should be replaced.

2. Measure cylinder wall wear as shown. If wear is excessive, compression pressure will decrease. Rebore the cylinder wall and replace the piston and piston rings. Cylinder wear should be measured at three depths with a cylinder bore gauge. (See illustration.)

|

|

Standard |

Wear Limit |

|

Cylinder bore |

65.00 mm (2.5591 in) |

65.005 mm (2.5592 in) |

|

Cylinder taper |

— |